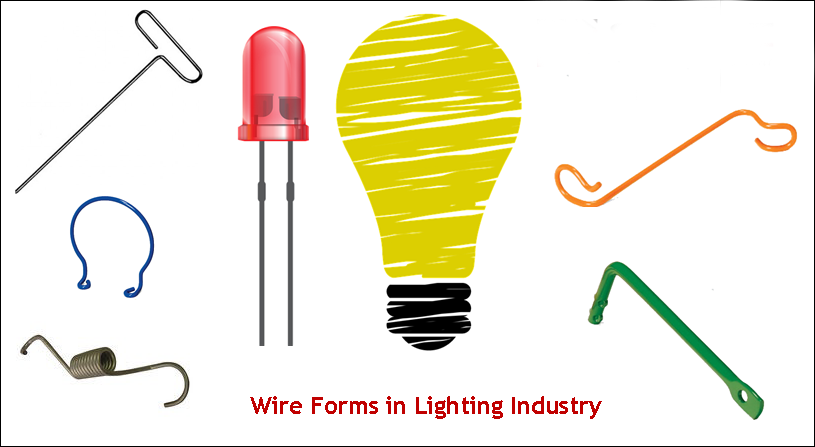

Custom wires refer to the dissected parts of the round or flat wires, which are used to create a finished product with necessary bend and angles. These wires are versatile, and can be customized in different forms. This makes them useful in diverse industrial applications. These wires are available in different shapes and sizes, and are manufactured using CNC machines. By using a varied diameter range wire on the CNC machines, custom wire forms of desired angles, straightness, and curvature can be produced. These wire forms can be used in a wide range of domestic, as well as industrial applications. The custom wire forms play a vital role in the lighting industry. This post discusses why these wire forms prove to be essential in the lighting industry.

How Custom Wire Forms are Manufactured?

Custom wire forms can be made from different materials, such as copper, brass, bronze, aluminum, chrome vanadium, berrilium, Hastelloy, Inconel, titanium and stainless steel. The aforementioned materials are used for manufacturing custom wire forms with a variety of surface treatment options, such as:

- Cleaning – Ultrasonic & Conventional

- Citric & Nitric Passivation

- Deburr – Vibratory & Tumble

- Heat Treating & Stress Relieving

- Anodizing

- Plating

- Laser Etching

- Rust Preventative

Advantages of Custom Wire Forms in Lighting Industry

Custom wire forms have a number of advantages in the lighting industry, some of which are as follows:

- Custom wire forms come in a vast variety of materials, from standard stainless steel to exotic materials. This provides a wider choice.

- These wire forms can withstand harsh chemical environments, and are heat and radiation resistant.

- Custom wire forms help reduce the overall product weight.

- Product’s operating efficiency is increased, when custom wire forms are used.

Wire forms are widely used in diverse lighting applications, where they are bent into clips to hold equipment and electrical wires together. To get more information about the custom wire forms, you can always contact an expert. CISI is one of the reputed custom wire manufacturers servicing a vast number of industries.