The Material of Choice for Corrosive Environments

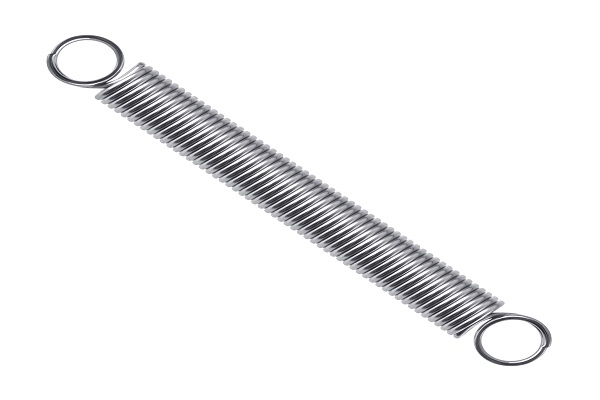

Music wire is a high-carbon steel alloy, which finds its major use in manufacturing springs. It is known to offer uniform and high tensile strength, and high elastic limit. Due to this, a music wire can endure high stress, still delivers outstanding performance under several normal recurring applications. CISI has an array of different types of springs made from this material.

Music Wire Springs Specifications

We have music wire springs of following specifications available with us:

| Maximum Working Temperature | 250°F |

| Weight (per cubic centimeter) | 7.85 gm. |

| Electrical Conductivity | 8-12% copper |

| Minimum Tensile Strength (psi x 103) | 230-399 |

| Rockwell Hardness | 42-46C |

| Density (lb/in3) | 0.284 |

| Plating Material | Copper, Bright Zinc, Zinc Phosphate , Dichromate, Black Oxide , Cadmium , Nickel , Tin-Lead , Tin |

Chemical Composition of Music Wire Springs

The chemical composition of these music wire springs are as follows

| Content | Percentage |

| Carbon | 0.70 – 1% |

| Silicon | 0.10 – 0.30% |

| Manganese | 0.20 – 0.60% |

| Sulfur | 0.030 max. |

| Phosphorus | 0.025 max. |

Properties of Music Wire Material

Music wire is a carbon-steel alloy. This material has some really exceptional properties, because of which they are widely used in spring manufacturing industry. Here are some of the important properties of the material:

- The carbon-steel alloy has high and uniform tensile strength

- It has a high shock load ability

- The alloy shows excellent fatigue properties

- Carbon-steel can undergo electromechanical, as well as non-electromechanical process

Advantages of Music Wire Springs

These types of springs offer several advantages. Some of them are as listed below:

- A music wire spring can survive a considerable stress due to its high tensile strength

- These springs are extremely versatile and can be used for a wide range of applications

- As music wire is a single piece, it eliminates the chances of unraveling

- These springs can fit into tight spaces, owing to its flexible nature

Applications

Due to its numerous advantages, music wire springs are widely used in various applications, which include:

- Small Aircraft Landing Gears

- Scaffold Cross-Bracing

- Antennas

- Surgical Instruments

- Musical Instruments

- Radio-Controlled Aircraft Engines

We are known to keep the design requirements of our customers at the forefront of operations. This helps us to serve our wide customer base in a better way. For all your queries as well as design requirements related to music wire springs, you can get in touch with us at inconel.springs@shapedparts.com. You can also give us a call on our toll free number +86-755-27478751.

Upload Your CAD Drawing

Upload Your CAD Drawing